The choice of glass is a fundamental part in the optical design process. This is especially true for IR and thermal optics materials. In this article, we will review Calcium Fluoride (CaF2), an interesting glass that has a wide range of applications.

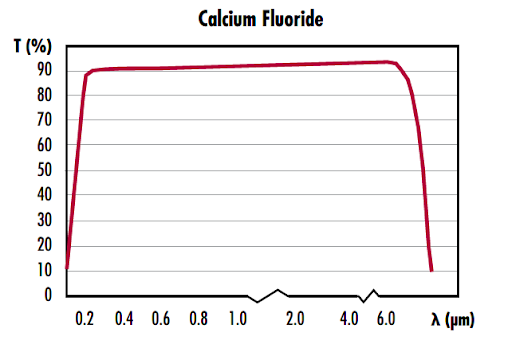

Before we start, let’s look at the transmission window for CaF2 (Figure 1). As we can see, it has an excellent transmission window with almost 90% transmission from 200 nm all the way to 7 um. What is interesting about this transmission window is that it is pretty consistent, an uncommon feature of optical glass.

Figure 1.Calcium Fluoride transmission window. Image from EdmundOptics

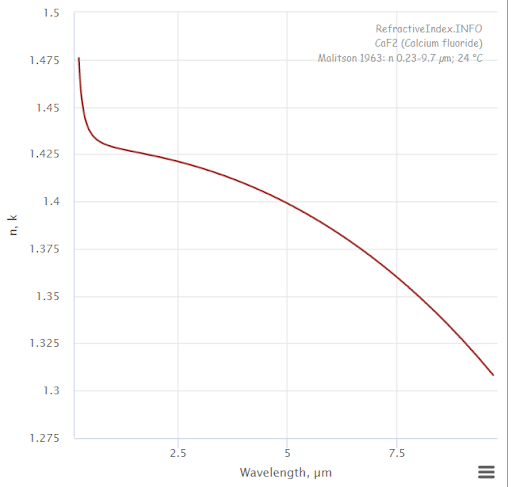

If we look at the changes in its refractive index, we will see a variation from 1.475 at 200nm to almost 1.3 at 9 um. The refractive index changes are not linear (Figure 2) and this property is commonly used to enhance CaF2 glass blanks so they can operate more efficiently in a particular window (UV, VIS or IR).

Figure 2. Calcium Fluoride refractive index. Image from refractiveindex.info

However, working with CaF2 is not easy. CaF2 is usually grown by vacuum in diameters up to 250 mm, which tend to create expensive blanks. As an example, a simple plano-convex CaF2 lens with a focal length of 100 mm and a 2 inch diameter costs around $350, while the same lens made out BK7 costs only a third of that price.

If an IR application is needed, the crystal can be grown using naturally extracted fluorite but these blanks tend to present absorption bands around 300 nm and have low transmission in the UV region. CaF2 and various combinations of fluoride compounds can be made into synthetic crystals with applications in lasers and special optics for UV and infrared

In commercial applications, Cannon uses CaF2 in some of their high-end optical lenses, as shown in Figure 3. One design architecture option used when designing an apochromatic lens is to use a Fluoro-crown glass such as FK51 in combination with a flint glass like KzFSN-2

Figure 3. Commercial application of CAF2 glass in high-end telephoto lens. Image from BHPhoto.com