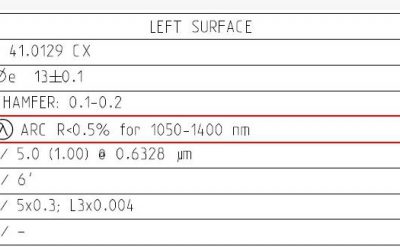

According to ISO 10110 standard, optical coatings are divided into protective and functional coatings. Protective types are coated onto optical elements when the safety of optical surfaces matters and a functional coating is needed. For example, an optical device to...

lens design

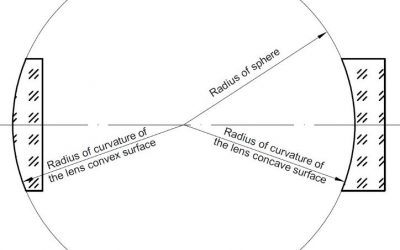

Radius of curvature requirement in optical drawings

by SergeySidorovich | lens design, optical design, optical engineering

Based on ISO 10110 standard, one of the key parameters in optical drawings is the radius of curvature of lens surfaces. It is specified on the first line of the surfaces column in the table of parameters. You can click here to review. The lens optical properties are...

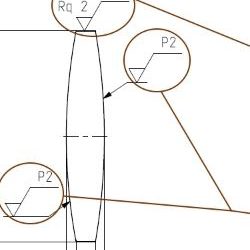

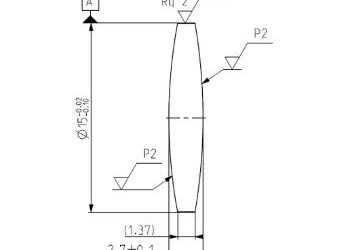

Surface texture requirement in optical drawings

by SergeySidorovich | lens design, optical design, optical engineering, optics

Updated June 2020. In our previous article, we discussed how to read optical drawings while in this installment, we will focus on surface finish details. Optical lens performance can be heavily affected by the lens surface roughness. The surface texture symbols are...

Mastering Optics Production Drawings: A Comprehensive Guide to ISO 10110 Standards

by John | lens design, optical engineering

Introduction Optics production drawings play a pivotal role in the manufacturing process of optical components, devices, and systems. These drawings serve as detailed blueprints that guide engineers, technicians, and manufacturers in fabricating precise and...

How to reverse engineer a lens.

by John | lens design, optical design, reverse engineering

Need assistance designing a custom optic or imaging lens ? Learn more about our design services here. Can you reverse engineer a custom lens? This is a question we get from time to time and the short answer is usually 'no'. There are vendors who can...