Planning to hire a lens design partner to assist with your optical engineering program? Here are a few things to consider.

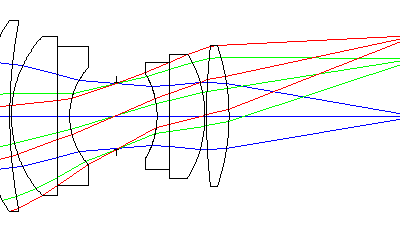

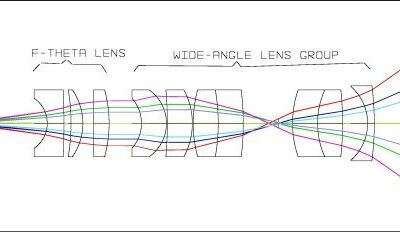

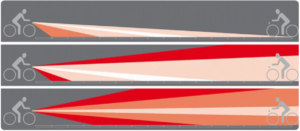

Do you need a lens for illumination or for imaging? The design methods and software tools used for illumination and imaging are different. Many optical engineers specialize in either sequential ray tracing (imaging) or non-sequential (non imaging/ illumination). Make sure your partner has expertise in the design type you need.

Who will be providing opto-mechanical design? A good optical design is as good as its opto-mechanical one. An experienced opto-mechanical engineer will provide important feedback on the mechanical and assembly tolerances that come out of the optical design . The give and take between the lens designer and mechanical engineer will result in a more robust optical system. At the start of your lens design, you should ensure your team includes both an optical and an opto-mechanical engineer.

What is your expected production method? Different lens production methods provide different levels of accuracy and tolerances. Your optical designer should be familiar with what can be achieved in the manufacturing processes that best match your production volume and requirements.

Has your optics consultant produced lenses for applications similar to yours? Optical design programs are agnostic when it comes to materials: the transmission, scattering, and refractive index are just data points used in lens optimization. When it comes to mechanical design and manufacturing, the materials used for different wavelength regions sometimes have unique characteristics. For example, it’s best to avoid finding out late in the process that the selected glass type that meets spectral requirements is so fragile that the lens vendor is unable to deliver acceptable production yields.

Need assistance designing a custom optic or imaging lens ? Learn more about our design services here.