According to ISO 10110 standard, optical coatings are divided into protective and functional coatings.

Protective types are coated onto optical elements when the safety of optical surfaces matters and a functional coating is needed. For example, an optical device to be used in a harsh environment requires a protective coating.

Functional types are coated onto optical elements to provide the necessary refractive or reflective coefficient.

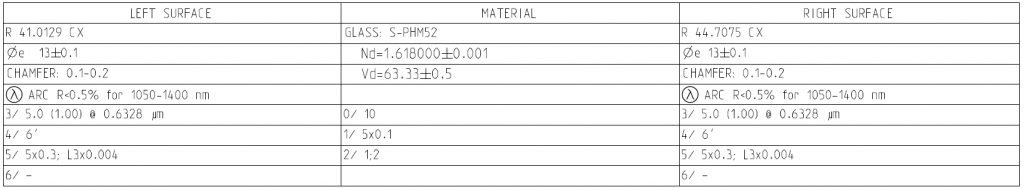

Let’s look at a drawing example of an optical lens production shown here. Locate the cell defining optical coating parameters in the surface requirements column. This cell looks like the image below.

Lens optical production drawing parameters

First of all, you will see a Greek letter with a circle around it. This mark indicates that a functional coating is needed. Then the ARC abbreviation follows, short for “Anti Reflection Coating”. This acronym defines the purpose of the coating. In this case, the coating decreases the reflection coefficient. The next inscription (R<0,5%) is the requirement for maximal reflection coefficient. Last is the wavelength range and optical coating requirements are defined for these wavelengths. In some cases, instead of a range, wavelengths are either more precisely defined or defined as sets of wavelengths. In those cases, the values are separated by commas.

Need help? Click here to learn more about our custom optical engineering services.

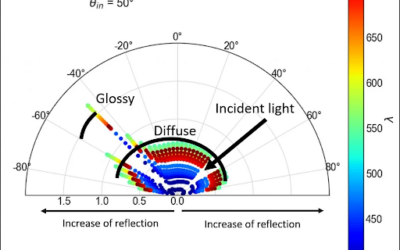

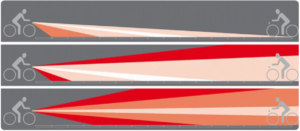

An optical engineer defines optical coating requirements not only from the optical system efficiency’s point of view. They also assess the influence of light reflected from the lens surface onto an image or sensor. Reflected or scattered light can destroy the image quality or worsen the signal to noise ratio making a precise coating definition an important design task.