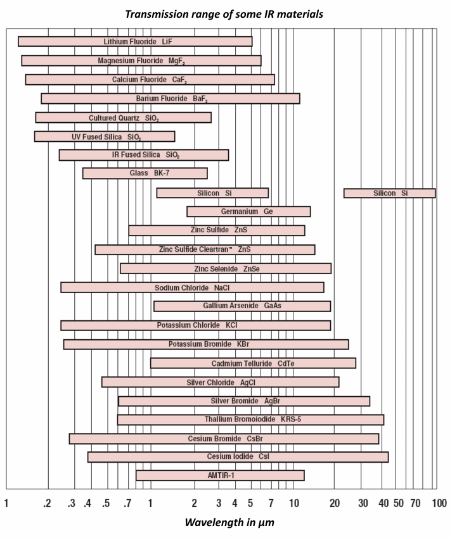

The selection of optical materials is a critical step in the design of infrared optics. Traditional optical materials (optical glasses and plastics) used in the design of visible radiation optics aren’t suitable due to their high light absorption coefficient in the infrared range. Special materials with minimal possible absorption coefficients for infrared light are required.

The list of suitable materials is relatively small and can be divided into three groups:

Crystalline and polycrystalline optical materials;

Semiconductor optical material;

Chalcogenide optical materials (chalcogenide glasses).

Original image owned by Janos Technology.

Need help? Click here to learn more about our custom optical engineering services.

Crystalline and polycrystalline optical materials

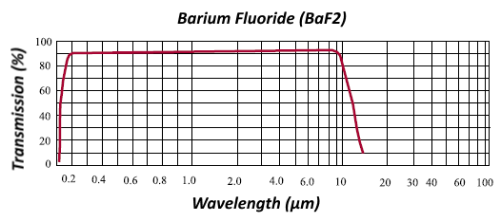

Crystalline and polycrystalline optical materials’ transmittance is as high for infrared as for visible region radiation. This makes it possible to design and produce multispectral optical devices. Such devices work with both infrared and visible light with minute adjustments and their efficiency will be sufficient. Assembly and adjustment of the multispectral devices is simpler than infrared devices because visible light can be used to control these operations. The downside is that many of these materials including Barium Fluoride (BaF2), Lithium Fluoride (LiF), Silver Chloride (AgCl), and Sodium Chlorides (NaCl) have low mechanical strength and chemical resistance .

A second potential disadvantage is a low refractive index: it rarely exceeds 1.5. As a result, additional optical elements must be used to achieve the required optical characteristics. This could increase complexity as well as cost of the optical system and its manufacture

The most suitable materials for production are crystalline and polycrystallines such as Zinc Selenide (ZnSe) and Zinc Sulfide (ZnS). These materials acquire optimal characteristics if they are manufactured according to CVD (Chemical Vapor Deposition) technology.

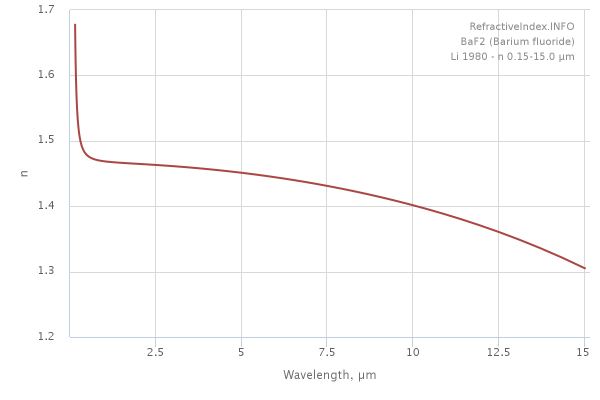

As an example, some optical characteristics of the Barium Fluoride (BaF2) are depicted below.

Original image owned by Janos Technology.

Original image owned by RefractiveIndex.INFO.

Semiconductor optical material

The main advantages of the optical semiconductor materials are their very high refractive index and low dispersion coefficient. This allows the design of optical systems with short focal length without the need for correction for chromatic aberration. This reduces the number of optical elements required and hence cost.

Semiconductor optical materials absorb visible light and their coefficient of absorption is rather high for infrared radiation. As a rule, it increases with increasing material temperature thus reducing their transmittance. An experienced designer avoids thick elements while using a minimal number of elements to preserve transmittance.

Optical devices which include semiconductor optical materials are harder to assemble and adjust because visible light cannot be used for this. This process requires special methods and equipment.

Semiconductor optical materials which are usually used in production of the thermal optics are Silicium (Si), Germanium (Ge), Cadmium Telluride (CdTe), and Gallium Arsenide (GaAs).

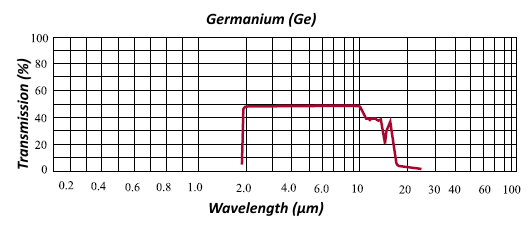

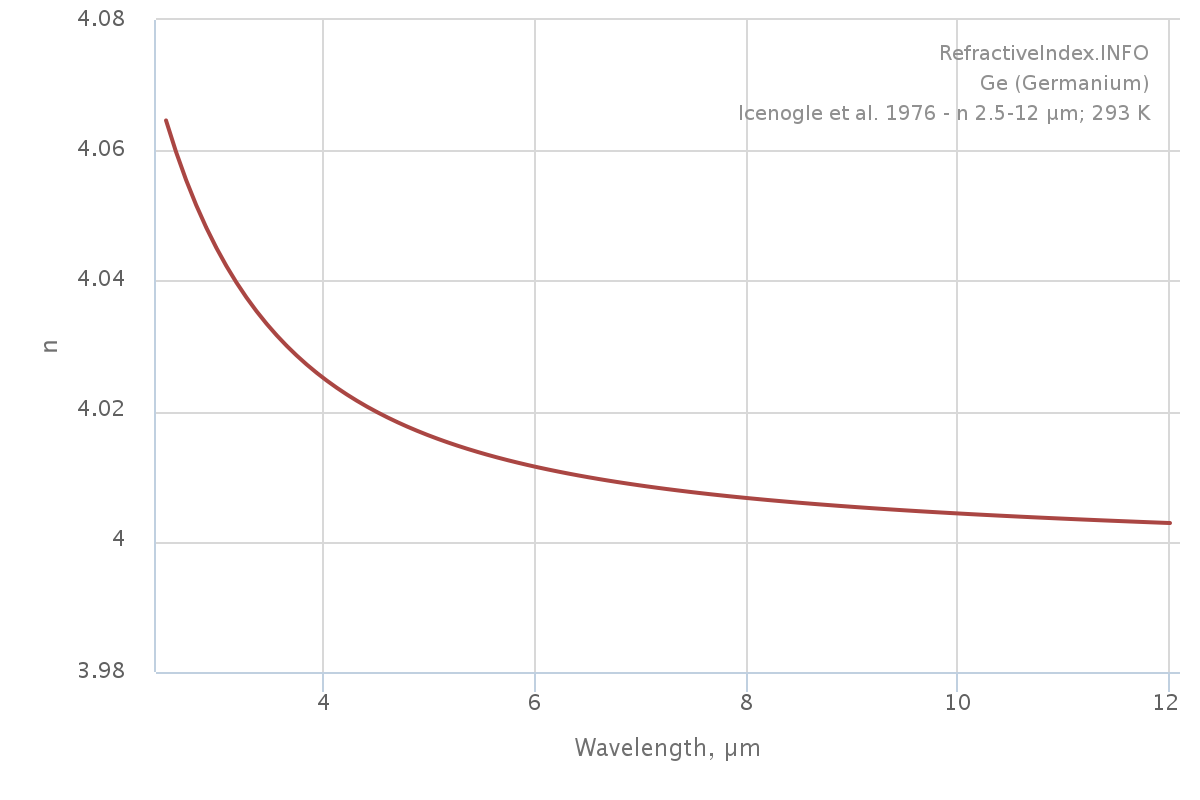

As an example, see below some optical characteristics of Germanium (Ge).

Original image owned by Janos Technology.

Original image owned by RefractiveIndex.INFO.

Chalcogenide optical materials (chalcogenide glasses)

Chalcogenide glasses have good bandwidth of infrared radiation but their refractive index is lower than that of semiconductor materials.

The main advantage of chalcogenide glasses is their very low refractive index temperature coefficient. This enables their use in the design of devices working in a very wide range of temperatures. The cost of these materials is however rather high. Some chalcogenide glasses include Amtir-1, IG6, BD2, and GASIR-1.

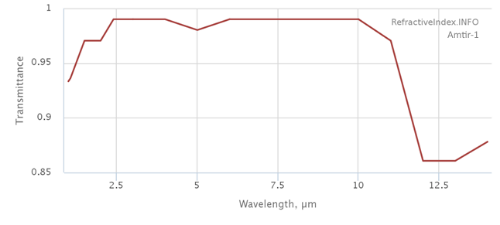

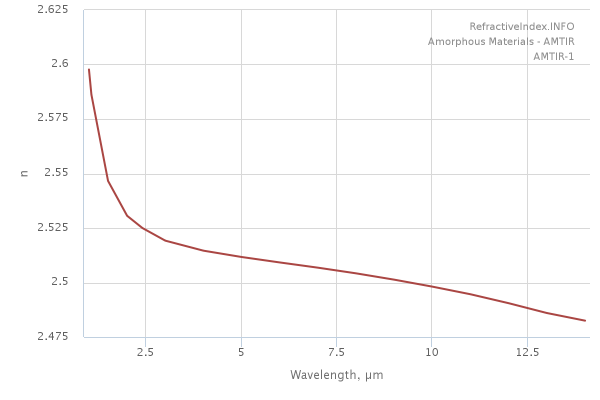

Below are depicted some optical characteristics of Amtir-1 as an example..

Original image owned by RefractiveIndex.INFO.

Original image owned by RefractiveIndex.INFO.

Want to learn more? This post provides a general overview of IR and thermal optics