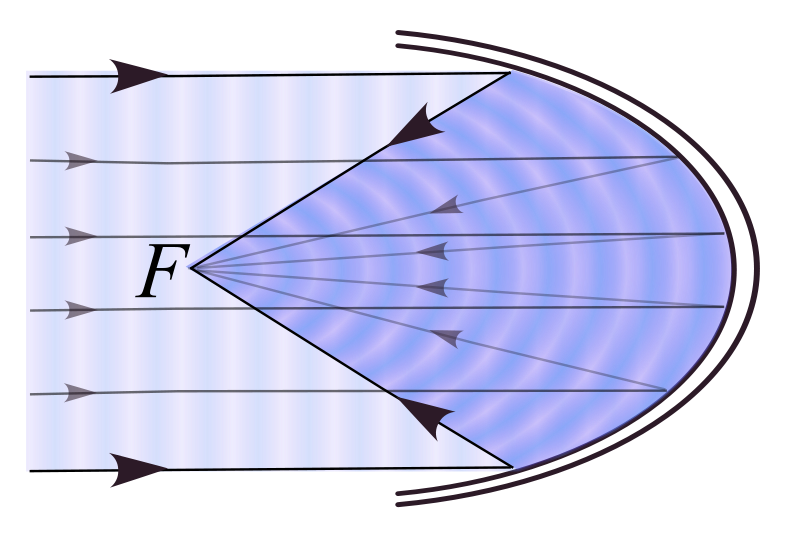

Parabolic mirrors are optical systems that are used to collect or distribute energy. They have a wide range of applications from solar collectors for water heating systems to microscopes and telescopes, and everyday flashlights. The most common way to understand parabolic mirrors is that a bundle of light beams parallel to the optical axis will reflect from the curved mirror surface and will focus on a single point. A parabolic mirror differs from a spherical one in that they greatly reduce spherical and coma aberrations.

Figure 1. Representation of a parabolic mirror. Parallel rays to the optical axis focus on a single point. Image from wikipedia.

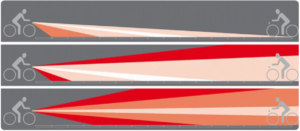

Off-axis Parabolic Mirror

One not so obvious problem with systems that use parabolic mirrors is that the receiver/collector has to be placed at the parabolic mirror focal point creating a shadow at the mirror surface and limiting the amount of energy that can be collected. One solution to this problem is using off-axis parabolic mirrors. Off-axis parabolic mirrors are basically sections of a parabolic mirror, usually a section that doesn’t include the vertex of the original parabola. The light beams are then focused away from the parabola in such a way that the receiver won’t create a shadow.

An important parameter when designing off-axis parabolic mirrors is the off-axis angle-the angle at which the light beams bounce off of the curved surface. The angle will depend on the section of the parabola that is used to create the off-axis mirror. The closer the section is to the parabola vertex, the smaller the angle will be.

Figure 2. Off-axis mirror. The off-axis angle is an important parameter that depends on the section of the parabola that is used to create the off-axis mirror. Image from Thorlabs.

When working with off-the-shelf optical components, this off-axis angle is limited to specific values (e.g. 15, 30, and 45-degrees). However, one of the advantages of having custom-made optics is that we can design this angle to your specific needs and use mirror coatings appropriate for the application and wavelengths.

To learn more about different mirrors used in optical systems, please see our previous post on ‘hot’ and ‘cold’ mirrors for UV and IR systems.