Design, Prototyping and Manufacturing of Custom Optics

OFH provides turnkey design and production of optical systems including lenses with mechanics and electronic controls. We support multiple production methods and volumes from 5 to 500,00 units

Custom Lens Manufacturing Stages

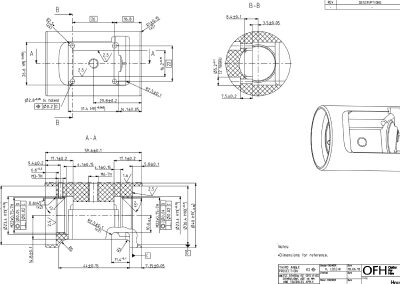

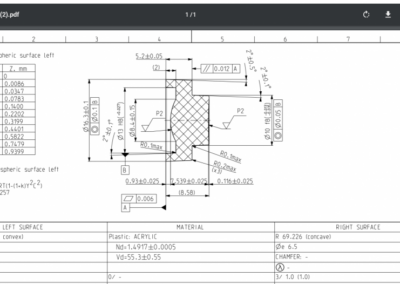

Documentation review: Lens Drawings should be drafted according to ISO standards (read more about lens drawings here), this will include material type, refractive index, tolerances for surface finish, thicknesses, coatings and more.

Molding or grinding and polishing of lens elements production methods are determined by production volume and complexity. OFH has a robust supply chain to support any production method and volume required.

Assembly for each element including optical elements, lens barrels, and adjustment mechanisms. Correct air gap, tilt and centration must be maintained when building multi element systems.

Lens Testing and validation: This might include measurement and testing of individual lens elements and/or completed assemblies. Mechanical properties will be measured and optical characters such as focal length, MTF and distortion may are commonly tested but optical testing is application specific add there is a wide range of possible metrology tests.

What Our Clients Say