The Edge Break Sensor

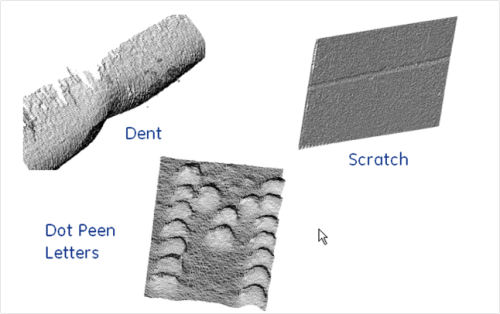

The edge break sensor is a compact handheld optical sensor prototype used by operators in the workshop environment to identify micron sized defects without the time consuming processing of taking a wax mold and measuring that mold on a profilemeter. The system was designed and built in partnership with a large industrial manufacturer and is undergoing field testing.

System Description

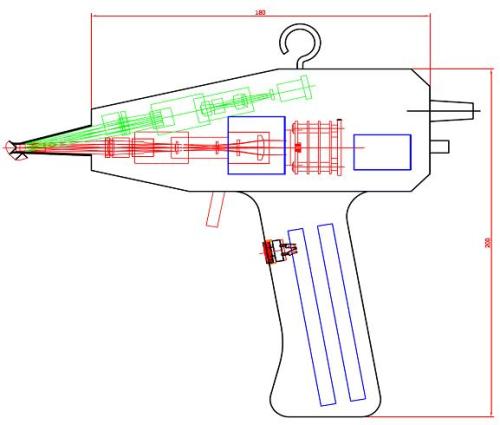

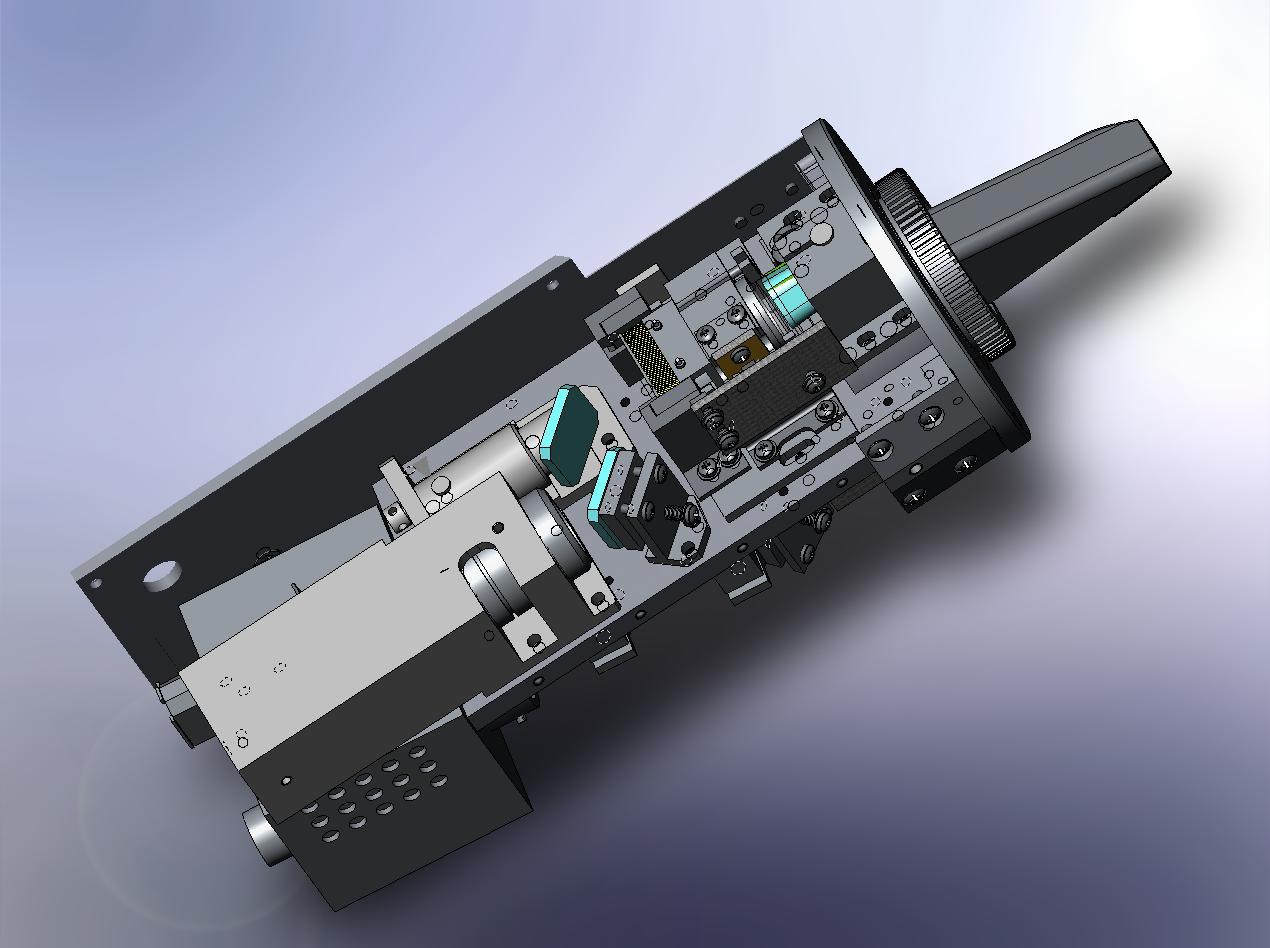

The handheld sensor captures surface profile information: it works by projecting a pattern of lines onto the region of interest and then capturing images of that pattern for evaluation with software. Using LED optics, this pattern in created by projecting a LED through a grating (shown in green). The grating sits on a piezo stage which moves to three positions.

A second optical channel includes a camera with a zoom and focusing lens (shown in red). This optical channel collects three images of the grating pattern. These three images are used by a software application to extract profile information.

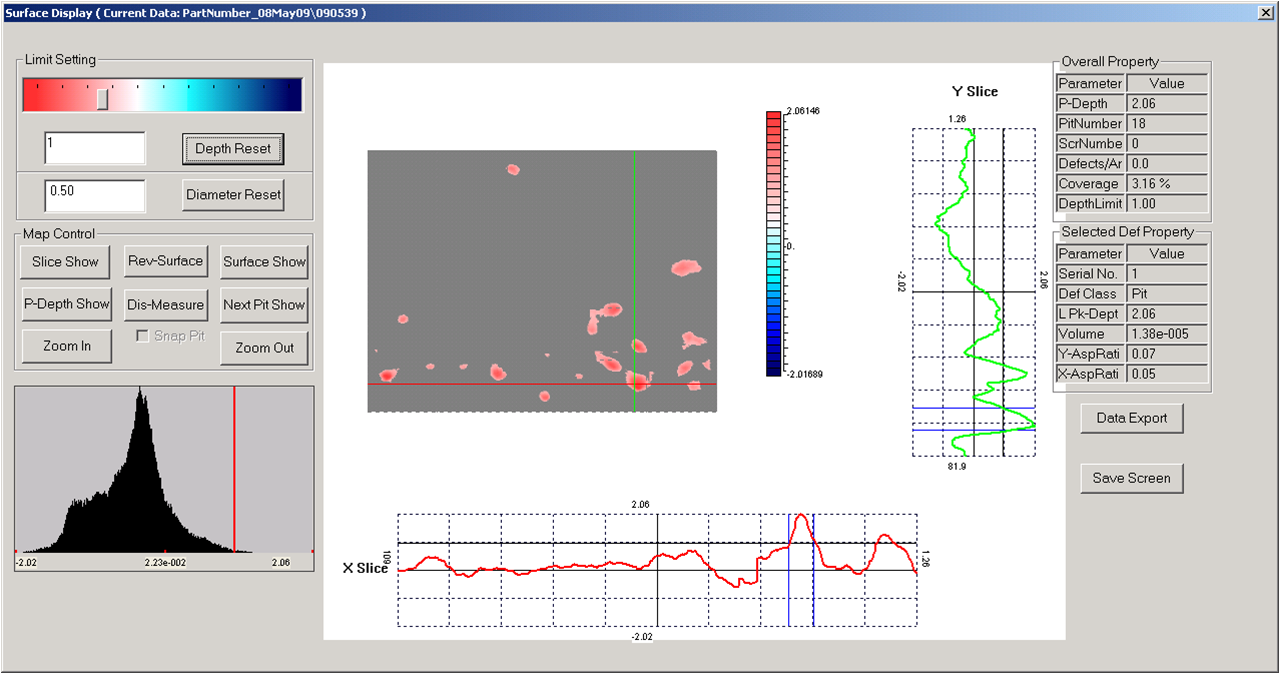

Software

Images

Specifications

| Requirement | Numerical value | Units |

| Measure radii max | 0.050 | Inch |

| Measure radii min | 0.005 | Inch |

| Resolution | 0.0001 | Inch |

| Absolute calibration | 0.001 | Inch |

| Measure straightness of facets | 0.0005 | Inch |

| Working Distance | Handheld, contact | |

| Field of View at part | 0.125 | Inch |

| Exposure Times | 1-100 | msec |

| Supply Voltage | 100 – 240 Volts AC/50-60 Hz | |

| Sensor Tips Provided | Straight, right angle, fast change | |

| Battery Backup | UPS with x hr capability | |

| Sensor Size | 8 x7 x 3 w/handle | |

| Sensor Focus | Manual | |

| Image and profile analysis platform | Windows XP PC | |

| Sensor Controller | Windows XP PC | |

| Sensor Interface | Firewire | |

| Light source | LED |