World Changing Collaborations

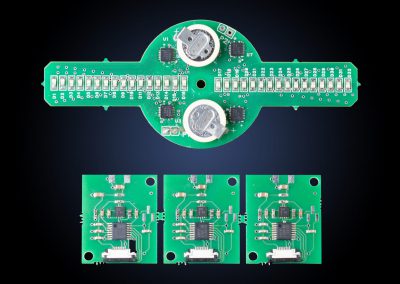

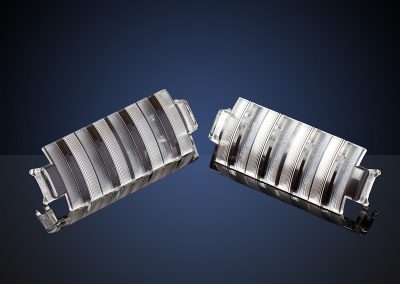

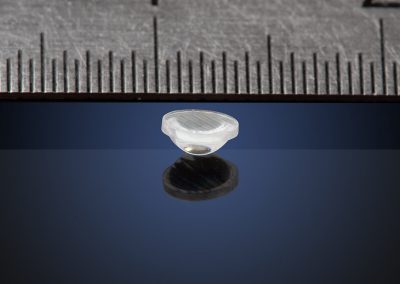

Custom lens design, prototyping and production

Engineering consultants to help you research, design, prototype, & manufacture optical systems

Optical modeling and ray tracing

Custom lens design

Complete opto-electronic/opto-mechanical systems

Applied optics research & consulting

Prototyping to volume manufacturing

of work history in optics, mechanics and opto electronics

optical systems

if it uses light we’ve worked on it

Optical, opto-mechanical and opto-electronic engineering consulting

We know how photons work and leverage our past experience to benefit your program

Project Feedback from University Client

“I have a background in optics, but lens design has always been a mystery to me. Your explanations helped me to decipher it.

Again, I am grateful for your expertise. It is a blessing for me to work with you and OFH.”

Project Feedback From Grow Light Startup

Project Feedback from Industrial Distance Measurement Company

“I want to take this opportunity to comment how impressed I am with OFH. Your team is moving so fast, I feel like a turtle. Also, it’s been noted that every time we ask something, our question is promptly answered and your team often brings up aspects that we haven’t considered.”

Our clients’ successful product launches

Getting Started and Working Together

- Tell us about your engineering challenges

- OFH reviews your requirements

- We provide feedback, ask for clarifications, explain performance trade offs

- Together we create a project plan to meet your performance, delivery time, budget goals

Typical project development process

- Development of requirements

- Feasibility review

- Preliminary subsystem specification development

- Development of requirements

- Feasibility review

- Preliminary subsystem specification development

Paper design, computations, simulations, and modeling

Concept development

Block diagram for optics, mechanics, and electronics

Optical design

Electronics design

Embedded software design

Mechanical design

Development of manufacturing documentation

- Prototype manufacturing and assembly

Testing of lens and subsystems

System debugging

Experimental measurements

Prototype delivery

Development of quality control processes

Delivery of system at volume

Recent Blog Posts

Understanding STVZO Bike Light Pattern and Optical Design

In the realm of bicycle lighting, adhering to stringent standards ensures not only compliance with legal requirements but also the safety and convenience of cyclists. One of the most critical standards in this domain is the STVZO (Straßenverkehrs-Zulassungs-Ordnung),...

Wobble Welding Explained

In the dynamic landscape of industrial manufacturing, advancements in welding technologies continually push the boundaries of precision and efficiency. Among these innovations, wobble welding has become an essential technique, combining the power of industrial laser...

Overview of Pi-Shapers, for beam shaping

The pi-Shaper, also known as the πShaper, is designed to transform Gaussian or similar intensity distributions of source laser beams into flat-top ones. This innovative technology has found applications in various industries due to its unique...