Since the start of the LED lighting revolution, plastic optics have been made primarily from acrylic (PMMA), polycarbonate or a modified version of either material (for example PMMI). More recently, silicon-based optical materials have grown in market share. These silicone resins are suitable for precise molding and can be used for refractive lenses, TIR lenses, reflectors, diffusers, and other optical components.

Key advantages of silicone resins include:

Resistance to UV light

Transmission more than 90% up to 350 nm

Usable in temperatures above 150°C, (acrylic deteriorates after 90° C, and polycarbonate after 30° C)

Allows optical designs that use thicker parts rather than polymer

Less yellowing

Lighter weight

Better impact resistance than polymers

Good chemical resistance: it resist acids, bases, solvents, chemicals, oils, and water

Very accurate reproduction of detailed shapes and features, such as optical surfaces, sharp edges, and small radii

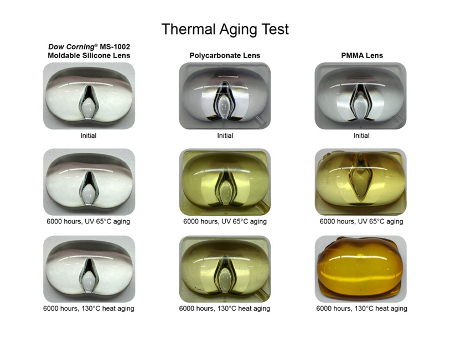

This test image above shows Methyl Silicone, a Dow Corning® MS-1002 and MS-1003 material

and Poly Carbondate and PMMA aging. Source: Dow Corning

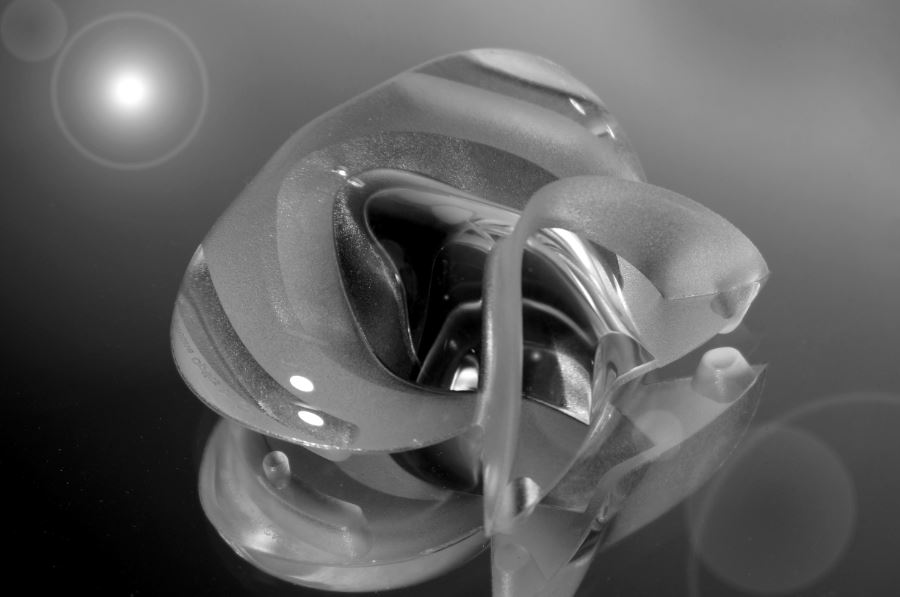

Complex design streetlight silicone lens made by Gaggione. Source: Gaggione

Need help? Click here to learn more about our custom illumination optic design services.